My Masters Thesis

Jesmonite AC100 as a Fill Material in Ceramics Conservation: An assessment into its ability to adhere to and be removed from ceramics.

Abstract

In ceramic conservation, selecting suitable fill materials is challenging, particularly for objects not stored in environmentally stable conditions, such as private homes or open displays. Current materials include plasters, acrylics, and epoxies, yet there is a need for a material that is affordable, humidity and UV resistant, visually sympathetic, durable, safe, and easily removable. This study investigates Jesmonite AC100, an acrylic-modified plaster, as a potential fill material.

Jesmonite combines properties of acrylic resin and plaster, forming a durable composite material due to an ionic bridge reaction (Phillips, 1995, p. 70). However, its adhesion to and removability from ceramic substrates were previously unexamined. Adhesion was tested using a 4-point bend test on six ceramic types: friable archaeological-style pottery, terracotta, low-fired glazed earthenware, soft stoneware, slightly porous porcelain, and vitrified porcelain. Cohesion failures occurred in softer ceramics, while adhesion failures were observed in porcelains only after substantial force was applied, indicating strong adherence across varying substrates.

Removability was assessed through a two-part experiment involving a solvent-saturated environment test and steam cleaning. Jesmonite AC100 was removable within an hour from porous ceramics using an acetone poultice within a closed solvent-saturated environment, while non-porous ceramics required 4–16 hours. Steam cleaning effectively removed residue from porcelain but was less effective on softer ceramics. Overall, Jesmonite AC100 adheres well across substrates and can be removed with acetone, but its strength suggests caution when used on softer ceramics. For these, off-object casting, and lower-adhesion adhesives are recommended.

For my report I created illustrations to visually support my descriptions of methodology as well as material-specific jargon to increase accessibility of my statements. Above are several of my illustrations, which I used Adobe Illustrator to create.

Problem

Jesmonite AC100, a two-part gypsum/acrylic composite system designed as a casting product for sculpture, interior architectural elements, and prop making, is a material which shows great promise for use in ceramics conservation. Related fields, such as marble (Coppola et al., 2018, p.343; Lewars & Mecani, 2019, p. 9), stone (Vatteroni, 2020, p.75) and paleontological conservation (Larkin et. al, 2021, p. 9) have recently begun using Jesmonite as both a fill material and as a replacement of plaster in high detail mold making (Baars, 2013, p. 36; Stable, 2012, p. 12), and it may have the capacity to become an essential material in conservator’s arsenal. However, two key characteristics are yet unknown: Does Jesmonite AC100 stick to ceramics without the use of additional adhesive and once it is set, can it be safely removed from the ceramic substrate? In ceramic conservation, the selection of appropriate fill materials presents a significant challenge, particularly when addressing objects that will not be housed in environmentally controlled, stable settings, such as those in private residences or on open display in historic homes or museums. There are currently several options for fill materials in ceramics conservation; however there remains a clear demand for a fill material that is not only costeffective but also resistant to humidity and UV light, visually compatible with a variety of ceramic types, durable, safe to use, and easily removable. This need is especially acute for complex, three-dimensional cast fills on objects that undergo frequent handling and elevated risk for mechanical damage. Understanding Jesmonite's properties could lead to safer, more efficient, and cost-effective conservation practices for ceramic objects, potentially revolutionizing the field with a new preferred material.

Aim

This research explores the suitability of Jesmonite AC100 as a fill material for ceramic conservation. The study will assess Jesmonite's adhesion to various ceramic types without additional adhesives and its potential removability.

Research Scope

Three-dimensional decorative elements on ceramic art are often subject to mechanical damage, leading to missing parts such as hands, figure heads and other protruding elements. This damage usually results from being knocked, dropped, or mishandled, causing these elements to become disassociated from the object. In ceramics conservation, the term "fill" refers to any recreated area of loss, including chips, glaze loss, missing fragments, and ornamental elements. Fills often suffer the same mechanical damage as the original substrate, with exceptions being degradation of the fill material itself or issues from humidity cycles; these factors may cause fills to detach or change shape. This study will primarily focus on damage caused by impact and mishandling. Secondary considerations will be given for using materials that are resistant to relative humidity (RH) fluctuations and colorfast, as these factors also affect frequently handled objects. Jesmonite AC100 is known for its high impact resistance and low moisture sensitivity, and long-term stability (Baars, 2013, p. 36), but its adhesion to ceramic substrates and reversibility remain untested. Understanding these factors is crucial, as a fill material with high cohesion and adhesion might transfer force to the original substrate– potentially causing more damage to the original object, making it unsuitable for conservation purposes.

Understanding the type of fill needed and the potential damage it may encounter, is crucial for selecting the right material. To identify fill types, a categorization system was developed based on professional practice and literature sources (Barov and Lambert, 1984, pp. 1-4; Buys and Oakley, 2014, p.120; Williams et al., 2002, p. 87). This study will focus on in-situ casted type C fills (see illustrations above) for objects at continued risk of mechanical damage.

Sample Preparation

Six types of ceramic bodies were selected to represent a range of qualities and porosities common in ceramics (table 4). To assess porosity, simple porosity tests were done by dropping one droplet of water onto the tile surface, waiting 2 seconds, and then absorbing excess water with the corner of a paper towel. Total absorption of droplet = highly porous, partial absorption of droplet and water darkening of the surface = slightly porous, no absorption and no surface darkening = not observably porous. Although the manufacturing process for tiles is different than that of cast or wheel-thrown ceramic objects, the material composition is consistent with other types of ceramics. This means that although the vulnerability to breaking will differ, the adhesion compatibility should be comparable.

To prepare the samples for the 4-point bend test and the removability experiments the following steps were taken:

Step 1: The tiles were all cut to 20mm x 45mm x 1mm tokens using a diamond wheel tile cutter lubricated with water.

Step 2: The cut tokens were air dried for three days, and then oven dried at 150˚C for 4 hours with an open oven door and the oven fan activated. The were allowed to rest on a wire rack for two more days

Step 3: Each token was put through a 4-point bend test to break them in half, data on the force required to break them was recorded to compare to the force needed to break the jesmonite-filled tokens.

Step 4: Using the manufacturer’s recommended mixing recipe, a batch of Jesmonite AC100 was mixed at 2.5-part powder to 1-part liquid and syringed into a prepared mold with individual cells measuring 20mm x 45mm in which halved ceramic tokens were set. This prepared 10 samples of each (6) ceramic body types.

Step 5: The Jesmonite was allowed to cure for 4 weeks before demolding.

Step 6: Each token was refined by hand using a flat scalpel blade and finished using a sanding wheel to cut back any uneven or overfilled areas. Measurements were taken with a micrometer to ensure the tokens were all within 0.5mm of 20mm x 45mm x 10mm.

Note: for the removability test an additional step is as follows:

Step 7: After demolding, the 5 filled tokens of 6 ceramic types were wrapped with 0.5 g of cotton wool around the interface between the substrates and then wrapped in overlapping top and bottom sleeves of transparent polyester film (fig 12). Melinex® was chosen over aluminum foil, which was used in Ramakers’ version, to observe the porosity of the sample through color changes. Additionally, the foil used in early tests Sayre 34 tended to bend and crease in a way which prevented free movement between the two sleeves. This may have had an impact on the sample’s ability to easily fall apart, so a solvent resistant material which slides along itself without creasing together was selected. Binder clips were clipped over the Melinex® onto each half of the sample, making sure that the clip did not accidentally cover the other half of the sleeve (figure 13)

Methodology

Test Design for Adhesion Test

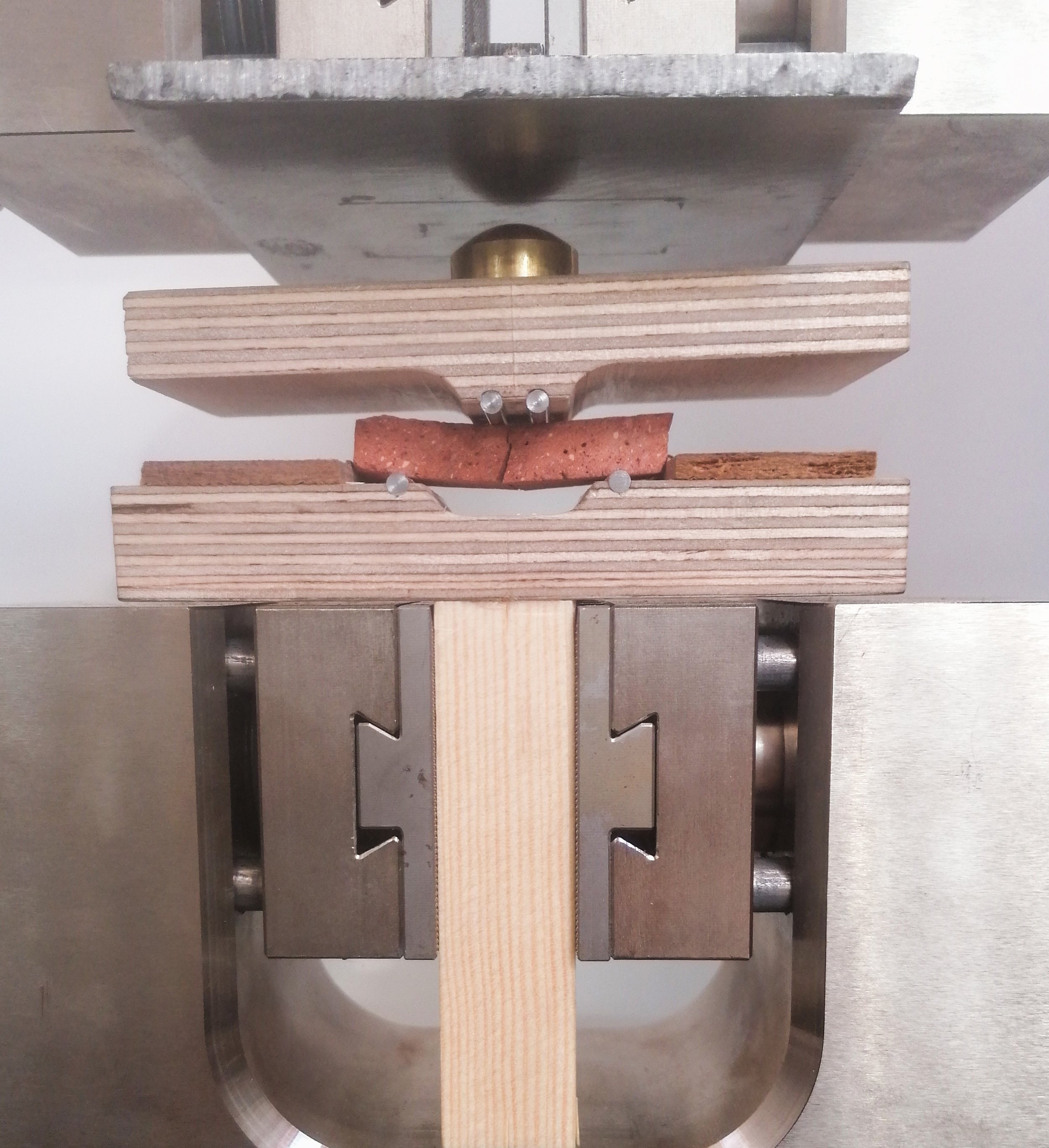

A ZwickRoell AllroundLine Tensile Test Machine was utilized with the preset ‘simple compression test’ setting which compressed a custom 4-point set up at 10 mm/min. This test design was inspired by multiple experiments which used a 3-point or 4-point bend test set up to evaluate the strengths of bulked adhesives used with plaster and ceramics (Alexiou et al., 2013, p. 12; Raedel et al., 2016, p. 156; van Beemen et al. 2013, p. 79), as well as the ASM International standard methods for testing ceramic tensile strength (Davis, 2004, p.163). Equipment Set-up can be seen in the photos below.

Test Design for Removability Test

Using the set-up illustrated in fig.13 each six ceramic types were attached to a wood board using a binder clip. Another binder clip over the lower sleeve and onto the fill half. A small weight (200g) was suspended from the binder clip using a wire hook, bringing the initial weight to 203.4g including the binder clip and weight support wire . Each sample was suspended vertically, using gravity and the additional weight to create a vertical load. The use of a weight is to provide a tensile force on the adhesive join to mimic the action of pulling apart softened adhesive joins after removing an object from the desiccator. In professional practice objects are placed in a solvent environment before being dismantled with some light tensile force applied to the sections when a conservator pulls apart the softened join.

Once all samples were in place with initial weights hung from samples 1-3 , syringes prefilled with 1ml of each solvent were used to inject the cotton wool through the Melinex® packet. A stopwatch was started at the injection of the first sample, and following samples will be injected at 1-minute intervals (each sample only injected 1x). The intervals were designed to allow a time cushion between injections so that each sample had the same amount of time exposed to each solvent. If this hadn’t been done, the time between injecting the first sample and the last would preferentially give additional solvent exposure time to the first sample, and accurately controlling that difference for in the data collection would be improbable.

The solvents were: deionized H2O and IMS in a 50:50 v/v solution, IMS, and Acetone. These solvents were selected after preliminary testing found unset (fresh mixed) jesmonite to be soluble in all of them, partially set4 (within 2-24 hours) Jesmonite AC100 to be removed from a ceramic substrate using swabs of each solvent and a scalpel, and set Jesmonite AC100 (after 48 hours) to be quickly (within a minute) removable with IMS, accompanied by mechanical prodding, from a glass surface (acetone and IMS + H2O solution not tested).

The time at which each sample drops away from the ceramic side was recorded, with solvent loading intervals considered. If the sample remained intact after 20 minutes, 50g weights were hung every 3 minutes from weighted samples until a maximum of 453.4g was reached. The additional weights are to signify slightly different tensile loads placed onto a bond when dismantling. The amount of tensile force needed to pull away a solvent softened fill was unknown, so multiple weight conditions were designed to explore this. A maximum allowed time for each ceramic type was 1 hour.

The times chosen were inspired by the maximum time taken for a sample to drop away in Ramakers’ study, the model from which the GASEST designed. The average time for ParaloidTM B-72 adhesive bond to fail was just under 10 minutes (Ramakers, 2013, p. 65). Being that ParaloidTM B-72 is known to be readily soluble in acetone, and the solubility of the acrylic portion of Jesmonite AC100 was yet unkown, the average time taken from Ramakers’ study was doubled to act as the basic interval (without additional weights).

The above photos are images taken from my thesis, for a more indepth description, my charts, my bibliography, and an expanded version of my methods and testing please reach out on my contact me page to request a copy of my thesis.

Adhesion Test Results

All four ceramic types which had lower original substrate 4-point break points than the solid Jesmonite AC100 samples failed in a ceramic substrate cohesive manner , thus failing the test. Both porcelain types, which have substantially higher 4-point break points than the solid Jesmonite AC100 samples, passed the test as the bond interface failed in an adhesive manner. All 6 types either failed or passed in the same way for each of the 5 samples. There was a variation in degree of failure with the Soft Stoneware samples. All 5 of the Jesmonite AC100 filled Soft Stoneware tokens failed the test, but unlike the Terracotta, Friable Archaeological-Style Pottery, and Glazed Earthenware samples, the Soft Stoneware samples failed in combinations of adhesion and ceramic substrate cohesive failure .

The average Fmax in the breaking of the filled Porous Porcelain samples was about 61% lower than the average Fmax in the breaking of filled Vitreous Porcelain samples, even though both substrates are classified as a type of porcelain. This was unexpected, as porosity of the ceramic substrate was suspected to contribute to the adhesion power of Jesmonite AC100 to the tile. Both substrates had similar break edges, with comparatively little key and matte textured surfaces. The main difference between the two porcelains was that the cohesive strength of the Porous Porcelain was much higher than the Vitreous Porcelain

Summary for Adhesion Test

Mechanical adhesion, through complex keying of Jesmonite AC100 into voids in the ceramic substrate appears to play a big part in its adhesion strength, however there is strong chemical adhesion as well occurring even on relatively flat surfaces. The weakest joint which failed through adhesive failure type d. (figure 1), occurred with the Porous Porcelain at 118 N (chart 3). The bond interface surface was 90mm2 ± 1.5mm2. 118 N equates to about 12.03 kg-force:

1 Newton (N) = 0.10 Kilograms-force (kgf)

so then, 118 N = 118 x 0.10 kgf

118 N = 12.03 kgf

Which means that to break this bond there had to have been at least 12.03 kgf per 90mm2, which can be simplified to approximately 1.34 kgf/cm2. To put this into an object handling context, a research project in which average grip strength of handling small objects of various fragilities was measured to be 12.5 ± 0.1 N amongst 14 able bodied university students (Gorniak et al., 2010, p.415). This is a tenth of the minimum Fmax to break the adhesion bond between Jesmonite AC100 and a porcelain substrate. Additionally relevant is the max possible grip strength. As part of NASA’s research into the effects of space travel on muscular health, the average maximum grip strength of their population sample (44 US male pilots and aviation cadets, and an unspecified number of US female pilots) was 596 N for males and 325 N for females (NASA, n.d.). It should be noted that this population sample are all trained US military personnel, thus the numbers are expected to be higher than the average person. Still, this information suggests it is highly unlikely that average or even rough handling of a Jesmonite AC100 filled ceramic object will cause the Jesmonite AC100 to detach. It might be possible to manually snap off a Jesmonite AC100 fill with a joint surface of at least 90mm2 from the porcelain substrates, though this is unlikely for most individuals. A Jesmonite AC100 fill on a non-vitrified ceramic body (softer than stoneware), which is cohesively weaker than Jesmonite AC100, will break the ceramic substrate before breaking the Jesmonite AC100 or breaking the adhesion bond.

Removability Test Results

Although the amount of time/weight needed to instigate the separation varied between the substrates, all successfully separated samples came apart by 25 minutes from injection of the acetone and required at least the minimum 203.4g weight to drop away. As shown in the table above all weighted samples exposed to acetone separated, except for the Vitreous Porcelain sample which loosened and fell apart during the set-up dismantling. The 50:50 IMS:H20 solvent did not separate any samples, and weighted IMS loosened the Porous Porcelain sample enough so that it came apart in the dismantling of the set-up. All unweighted acetone samples of each ceramic substrate loosened enough to come apart in the dismantling of the set-up.

Summary for Removability Test

Acetone was successful in separating Jesmonite AC100 fills from most substrates and loosened them from all substrates. Neither of the two other solvent conditions separated the fills. Except for the weighted IMS Porous Porcelain sample, none of the other solvent conditions loosened the fills from the original ceramic substrate. It is unclear if this was due to a fault in the adhesion of the cast Jesmonite AC100 to the ceramic substrate or if IMS effectively loosened the Jesmonite AC100. Because this effect was not observed in any of the other IMS samples, it might have been due to a sample preparation error. According to the results of the 4-point bend adhesion test the adhesion strength on the Porous Porcelain was the weakest. All samples which separated did so within 25 minutes, which indicated that the removal of Jesmonite AC100 fills is relatively easy to remove from ceramic substrates with acetone.

Discussion

The 4-point bend adhesion tests confirmed that Jesmonite AC100 forms strong bonds with diverse ceramics. However, its adhesive and cohesive strength exceeds the cohesive strength of softer ceramics, leading to substrate failure when exposed to complex stress states. While this indicates robust adhesion for durable ceramics, it also suggests that Jesmonite AC100's adhesive strength may not be appropriate for lower fired ceramics. Off-object casting of Jesmonite AC100 fills and bonding them with a lower-strength adhesive could mitigate this issue. An alternative approach would involve applying a barrier layer, such as ParaloidTM B72 or other permanently soluble primers, to facilitate controlled separation. Such barrier layers, commonly referenced in conservation literature (e.g., van Beemen et al., 2013, p.79), require further research to optimize their concentration and compatibility with Jesmonite AC100.

The GASEST illustrated the effectiveness of acetone in separating Jesmonite AC100 fills from all tested ceramic substrates. A minimum applied weight of 203.4 g was needed to detach the fill, highlighting the need for slight force in addition to solvent action. This mirrors common conservation practices where fills are gently lifted after solvent exposure. Notably, the desiccator method using acetone fumes to prepare samples for the residue removal section took substantially longer than the liquid acetone poultice in GASEST to release the fill. This variation is evident with ParaloidTM B-72 Podany's results- maximum of 6 hours for the tokens to separate (Podany et al., 2001, p. 27) achieved with a desiccator, versus Ramakers’ resultsa maximum of 12 minutes for the tokens to separate (Ramakers, 2013, p.65) achieved using a poultice set-up like the method developed later adopted in this study.

For residue removal, steam cleaning effectively reduced powdery and inclusion-based Jesmonite AC100 residue in hard or medium ceramics but did not much alter the amount residue embedded in softer or more porous ceramics. This outcome suggests the need for additional residue removal methods, such as solvent swabbing and mechanical picking, for thorough cleaning.

The combined findings from the 4-point bend adhesion tests, GASEST, and steam cleaning assessments suggest that Jesmonite AC100 is a viable and promising fill material for harder ceramics, given its robust adhesion, ease of removability, and tendency to fail adhesively under complex stress. However, for medium to low-fired ceramics, caution is advised due to Jesmonite AC100's tendency to cause substrate damage under bending stress. Casting fills off the object and bonding them with an appropriate adhesive could minimize the risk of damage to the original ceramic. Applying a barrier layer may also prevent Jesmonite AC100 from directly bonding with the substrate, reducing potential risks to original material integrity.

Conclusion

The aim of this study was to provide a comprehensive analysis of Jesmonite AC100’s suitability as an in-situ fill material for ceramics, focusing on its adhesive strength and controlled removability. Findings suggest that Jesmonite AC100 is highly effective for durable ceramic fills. The material's capacity for removal within an acetone-saturated environment further supports its suitability in scenarios where reversibility is required.

However, while Jesmonite AC100 shows potential as a fill material for harder ceramic substrates, conservators must remain cautious of its impact on softer materials. The results of the 4-point bend adhesion test indicate that off-object casting, and lower-adhesion materials should be prioritized, or used alongside Jesmonite AC100 for softer ceramics, as Jesmonite’s high cohesion and adhesion are much higher than that of soft to medium ceramic bodies and will preferentially break the ceramic substrate over the adhesive bond or the fill. In a situation where an object is put under high complex stress states, as modeled in the 4- point bend adhesion test, in-situ Jesmonite AC100 fills compromise the integrity of more fragile objects.

The two-part experiment involving the GASEST and steam cleaning test, indicated that Jesmonite AC100 is reliably removable with acetone, and remaining residues are reducible from medium to harder ceramics to the point they are no longer observable under normal visible light.

This research underscores the necessity for context-specific material choices in ceramic conservation. Future studies may explore modifications to Jesmonite AC100 or develop alternative materials that maintain similar resilience while adapting to a broader range of ceramic substrates. Ultimately, Jesmonite AC100’s performance across various tests confirms its viability in scenarios where strength, durability, and targeted removability are essential, positioning it as a valuable, albeit carefully applied, option within the conservation toolkit for durable ceramic restoration.